POLAR LabelSystem SC-21

Efficient industrial production of square-cut labels

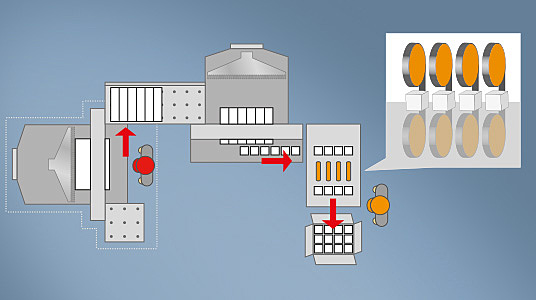

In square-cut label production the POLAR LabelSystem SC-21 provides maximum efficiency, because production steps are carried out in parallel mode. First of all, a POLAR high-speed cutter cuts the label material to strips, either in-line or off-line. Finishing is carried out on the automatic cutter POLAR Autocut 115, the central component of LabelSystem SC-21.

The workflow:

The precut strips are manually positioned on the POLAR LT-S loading table, before they are pushed onto the Autocut rear table. In the Autocut 115 the strips are arranged on the rear table with their sides and front precisely aligned.

After the labels have been cut, they are automatically arranged on the front table. A deloading device pushes them into the BM-105 multi-station bander. After that the row pusher takes the complete label row to the banding device. Once the packs are completely banded they are pushed further onto the delivery table and can be manually removed for packaging.

| Technical Data | |

| Label size, min. (depending on the clamp opening) | 20 x 43 mm |

| Label size, max. | 230 x 1050 mm |

| Clamp opening, min. | 30 mm |

| Clamp opening, max. | 120 mm |

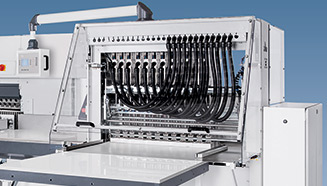

| Banding stations, max. | 18 units |

| Performance in automatic operation, max. (depending on the material and/or label size) |

5 cycles / minute |